The DT family of valves incorporate a combination of design features to provide solutions required to address a number of oilfield drilling functions where conventional designs have significant reliability issues.

Conventional downhole Non Return Valves were originally designed to prevent backflow in the drillstring when shutting down drillstring circulation to prevent motor damage or bit nozzle plugging with drilling debris. As drilling techniques have developed and particularly with the advent of underbalanced and managed pressure drilling techniques the demands on these valves have increased such that now they are required to reliably hold pressure from below to allow connections at surface to be made. Reliability of conventional valves has proved an issue in terms of low pressure differential sealing, tool washout and return spring damage leading to significant non-productive drilling time in some cases compromising the drilling and reservoir objectives.

Tools Specifications

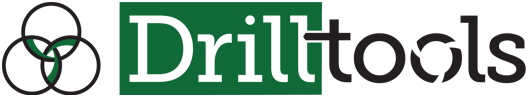

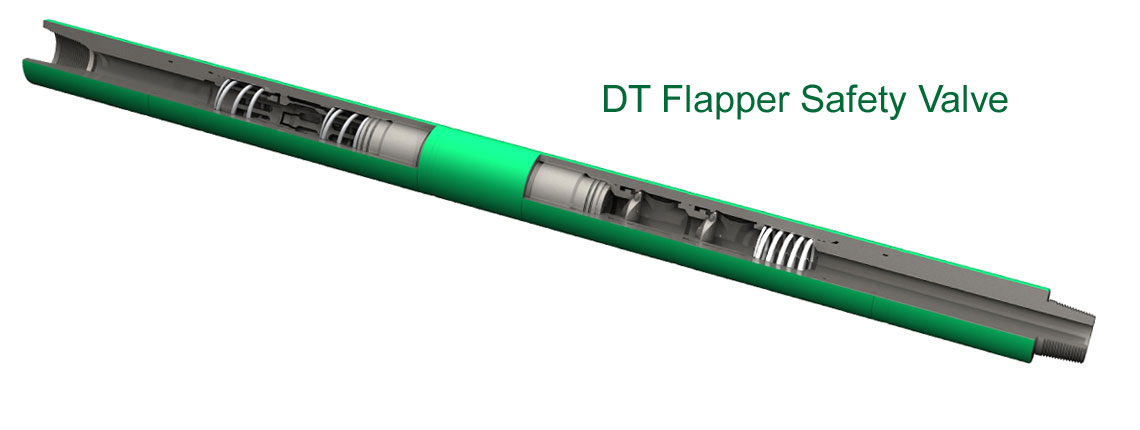

The DT 8¼" FSV utilises a curved flapper to optimise wall thickness and pressure rating, while minimising flow velocities and associated body and seal erosion through the valve. The valve is intended primarily for use as a drilling downhole non return valve where the valve not only has to prevent backflow but is required to retain a pressure differential (for example in Managed Pressure Drilling or Underbalanced Drilling situations). Elastomer technology is used to ensure a pressure seal at low differential pressures with the valve design preventing seal washout. The unique features of valve design allow an external to internal working pressure rating of 15,000 psi. In addition, the DT 8¼" FSV has a body working pressure rating of 15,000 psi and can be supplied with a solid flapper with working pressure rating (below flapper) of 15,000 psi. The valve is available in both standard and sour (H2S) service.

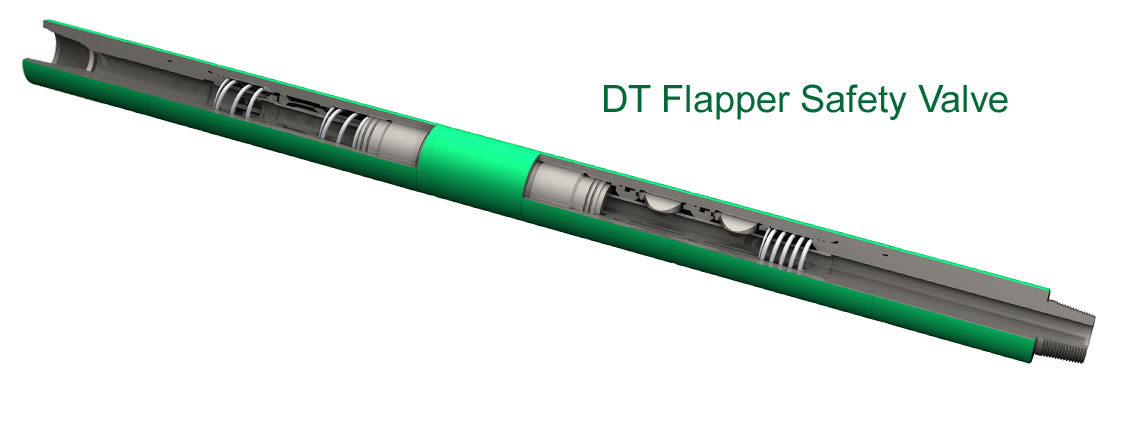

The valve is available in a downhole or surface configuration. The surface configured tool has a lock open sleeve facility to allow the passage of wireline. Both standard service and H2S service tools have a 8¼" outside diameter with a 2¾" inside diameter as run. If the lock open sleeve is installed in the surface configuration valve the inner diameter is reduced to 2¼".

| Internal Pressure Below Valve | 15,000 psi |

| Internal Pressure Body | 15,000 psi |

| External Pressure (collapse) | 15,000 psi |

| Tensile Yield | 2,700,000 lbs |

| Torsional Yield | 140,000 ft-lbs |

| Tool OD | 8.25" |

| Tool ID | 2.75" |

| Sleeve ID | 2.25" |

| Effective Length with Lock Open Sleeve | 111.125" |

| Effective Length without Lock Open Sleeve | 68.5" |

| Internal Pressure Below Valve | 15,000 psi |

| Internal Pressure Body | 15,000 psi |

| External Pressure (collapse) | 15,000 psi |

| Tensile Yield | 1,800,000 lbs |

| Torsional Yield | 93,000 ft-lbs |

| Tool OD | 8.25" |

| Tool ID | 2.75" |

| Sleeve ID | 2.25" |

| Effective Length with Lock Open Sleeve | 111.125" |

| Effective Length without Lock Open Sleeve | 68.5" |

The DT 7" FSV utilises a curved flapper to optimise wall thickness and pressure rating, while minimising flow velocities and associated body and seal erosion through the valve. The valve is intended primarily for use as a drilling downhole non return valve where the valve not only has to prevent backflow but is required to retain a pressure differential (for example in Managed Pressure Drilling or Underbalanced Drilling situations). Elastomer technology is used to ensure a pressure seal at low differential pressures with the valve design preventing seal washout. The unique features of valve design allow an external to internal working pressure rating of 15,000 psi. In addition, the DT 7" FSV has a body working pressure rating of 15,000 psi and can be supplied with a solid flapper with working pressure rating (below flapper) of 15,000 psi. The valve is available in both standard and sour (H2S) service.

The valve is available in a downhole or surface configuration. The surface configured tool has a lock open sleeve facility to allow the passage of wireline. The standard service tools have a 7" outside diameter with a 2¾" inside diameter as run, with internal components common to the 8¼" outside diameter tools. If the lock open sleeve is installed in the surface configuration valve the inner diameter is reduced to 2¼".

The sour (H2S) service valves have a 7" outside diameter with a 2¼". inside diameter as run. If the lock open sleeve is installed in the surface configuration valve the inside diameter is reduced to 1¾".

| Internal Pressure Below Valve | 15,000 psi |

| Internal Pressure Body | 15,000 psi |

| External Pressure (collapse) | 15,000 psi |

| Tensile Yield | 1,619,800 lbs |

| Torsional Yield | 67,500 ft-lbs |

| Tool OD | 7.0" |

| Tool ID | 2.75" |

| Sleeve ID | 2.25" |

| Effective Length with Lock Open Sleeve | 110.5" |

| Effective Length without Lock Open Sleeve | 68.5" |

| Internal Pressure Below Valve | 15,000 psi |

| Internal Pressure Body | 15,000 psi |

| External Pressure (collapse) | 15,000 psi |

| Tensile Yield | 1,150,300 lbs |

| Torsional Yield | 48,000 ft-lbs |

| Tool OD | 7.0" |

| Tool ID | 2.25" |

| Sleeve ID | 1.75" |

| Effective Length with Lock Open Sleeve | 111.125" |

| Effective Length without Lock Open Sleeve | 68.875" |

The DT 4¾" FSV utilises a curved flapper to optimise wall thickness and pressure rating, while minimising flow velocities and associated body and seal erosion through the valve. In 4¾" the valve is used as a drilling downhole non return valve where the valve not only has to prevent backflow but is required to retain a pressure differential (for example in Managed Pressure Drilling or Underbalanced Drilling situations). Elastomer technology is used to ensure a pressure seal at low differential pressures with the valve design preventing seal washout. The unique features of valve design allow an external to internal working pressure rating of 15,000 psi for the standard service valve and 10,000 psi for the H2S service valve. In addition, the DT 4¾" FSV has a body working pressure rating of 15,000 psi and 10,000 psi respectively is supplied with a solid flapper with working pressure rating (below flapper) of 15,000 psi and 10,000 psi respectively.

The standard and H2S service tools have a 4¾" outside diameter with a 115⁄16" inside diameter as run.

| Internal Pressure Below Valve | 15,000 psi |

| Internal Pressure Body | 15,000 psi |

| External Pressure (collapse) | 15,000 psi |

| Tensile Yield | 931,300 lbs |

| Torsional Yield | 25,500 ft-lbs |

| Tool OD | 4.75" |

| Tool ID | 1.313" |

| Effective Length without Lock Open Sleeve | 65.375" |

| Internal Pressure Below Valve | 10,000 psi |

| Internal Pressure Body | 10,000 psi |

| External Pressure (collapse) | 10,000 psi |

| Tensile Yield | 620,900 lbs |

| Torsional Yield | 17,000 ft-lbs |

| Tool OD | 4.75" |

| Tool ID | 1.313" |

| Effective Length without Lock Open Sleeve | 65.375" |